Data is everywhere. It lives in dashboards. It flows through pipelines. It fills cloud storage buckets. But what if your data could become something you can actually hold in your hand? What if your model predictions turned into metal parts, cut with precision and ready for the real world? Welcome to the place where data science meets CNC machining.

TLDR: CNC machining turns digital designs into real physical parts. Data scientists can play a big role by optimizing designs, improving processes, and reducing waste. By understanding how machines read data and convert it into motion, you can build smarter, faster, and cheaper manufacturing systems. This guide breaks it down in simple steps so you can move from data to parts with confidence.

CNC stands for Computer Numerical Control. That sounds fancy. But the idea is simple. A computer tells a machine how to move. The machine cuts material. The result is a part.

Think of it like a 3D printer. But instead of adding material, most CNC machines remove it. They start with a block of metal or plastic. Then they carve it into shape.

As a data scientist, this should excite you. Why? Because CNC machines run on data. And data is your home turf.

Contents

Step 1: Understand the Digital Thread

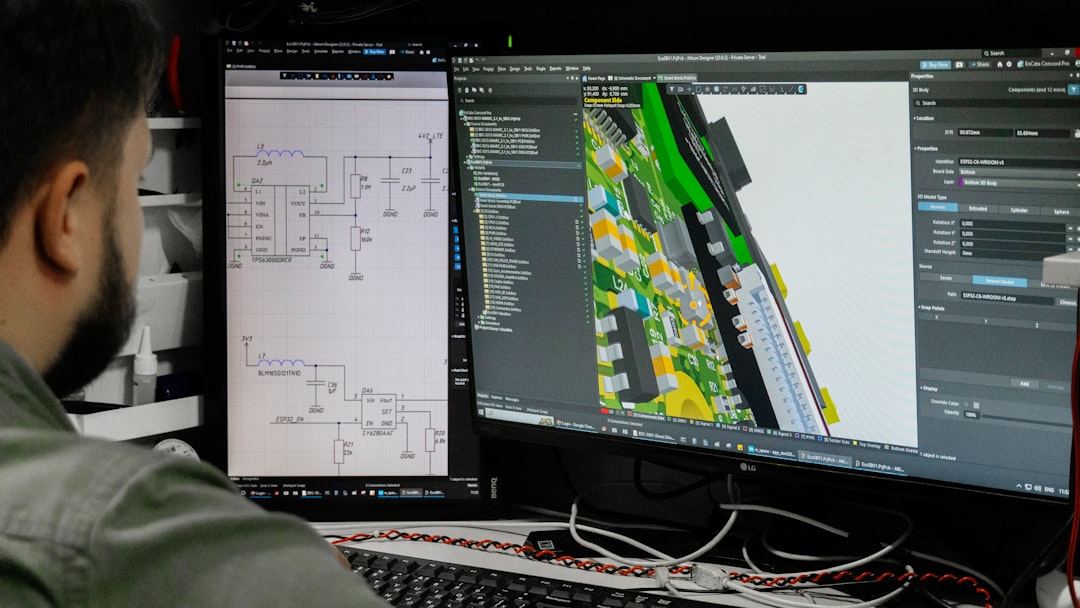

Everything in CNC starts with a digital design. Usually, this is a CAD file. CAD means Computer Aided Design. Engineers create 3D models of parts. These models include dimensions, tolerances, and geometry.

[p]Image not found in postmeta[/p]

But the machine cannot read a CAD file directly. It needs instructions. This is where CAM software comes in. CAM stands for Computer Aided Manufacturing.

CAM converts geometry into toolpaths. Toolpaths are step-by-step instructions that tell the cutter where to move.

Finally, these toolpaths are translated into G-code. G-code is the language of CNC machines. It looks like this:

- G01 X10 Y5 F200

That one line tells the machine to move in a straight line to a position. Simple commands. Precise movement.

As a data scientist, you should see this clearly. This is a pipeline:

- CAD model

- CAM processing

- G-code output

- Machine execution

Just like raw data to model predictions.

Step 2: Treat Machining Like an Optimization Problem

CNC machining is full of trade-offs. Speed versus quality. Tool life versus productivity. Cost versus precision.

Sound familiar?

This is classic optimization.

Some key variables include:

- Spindle speed – how fast the tool spins

- Feed rate – how fast the tool moves

- Depth of cut – how much material is removed per pass

- Tool selection – type and shape of cutting tool

Each variable affects:

- Surface finish

- Tool wear

- Cycle time

- Energy use

This is a multi-objective optimization problem. Perfect for machine learning.

You can build models that predict:

- When a tool will fail

- How long a job will take

- Surface roughness results

- Probability of part defects

Now you are not just cutting metal. You are engineering intelligence.

Step 3: Collect the Right Data

No data. No model. No magic.

Modern CNC machines are packed with sensors. They generate rich time-series data. Examples include:

- Spindle load

- Vibration

- Temperature

- Axis position

- Power consumption

This is manufacturing telemetry.

But raw machine data can be messy. It may include noise. Missing values. Different sampling rates.

Your job is to:

- Clean the signals

- Align time steps

- Detect anomalies

- Engineer meaningful features

For example, vibration spikes might correlate with tool wear. Rising spindle load might signal material inconsistency.

Think like a detective. What patterns predict failure? What behaviors signal stability?

Once you structure this data, you can train models that improve machining in real time.

Step 4: Simulate Before You Cut

Machining mistakes cost money. Materials are not cheap. Broken tools are worse.

That is why simulation matters.

[p] [/p]

[/p]

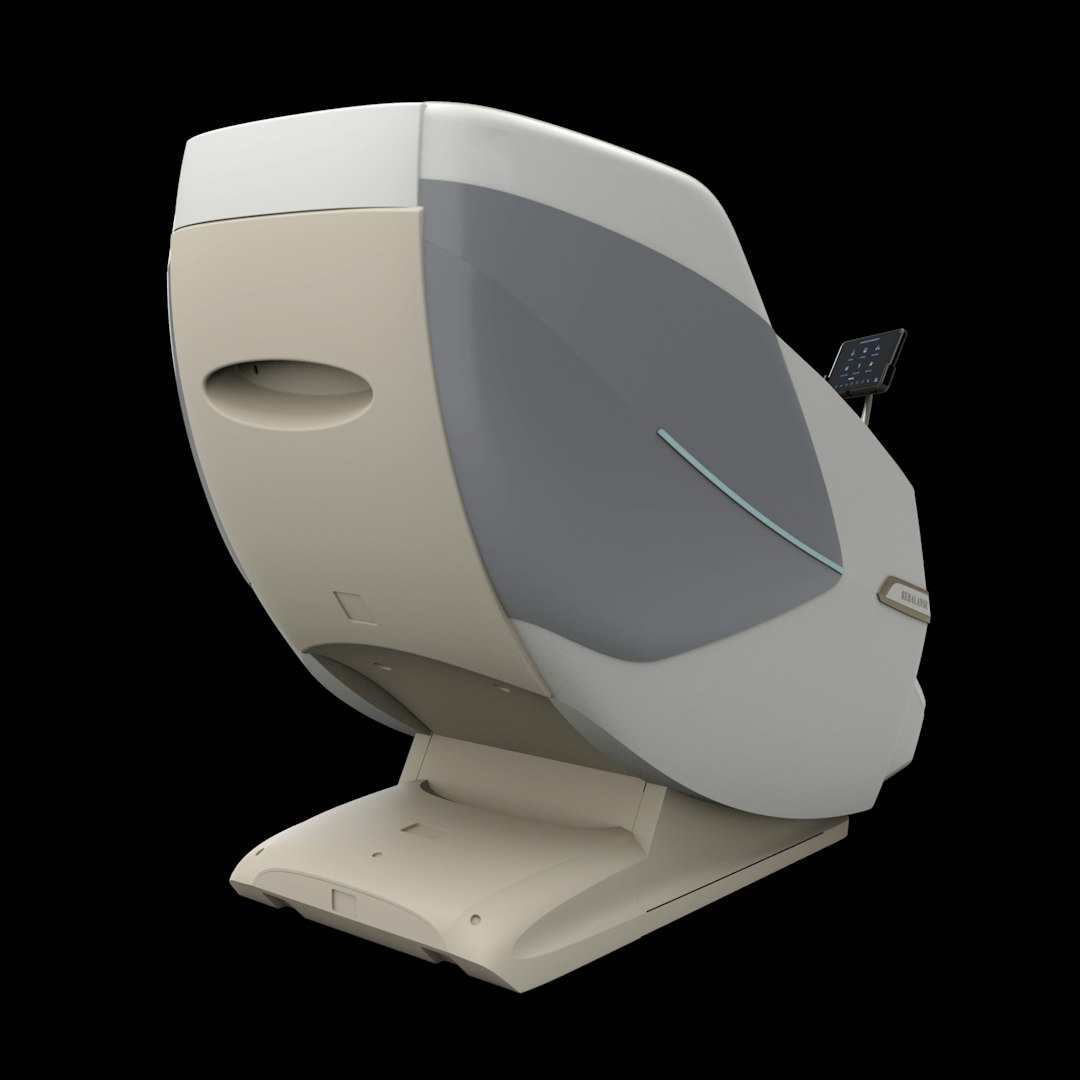

Before sending code to a real machine, manufacturers simulate the process. They check for:

- Tool collisions

- Excessive tool load

- Inefficient movements

- Uncut material

This is a digital twin. A virtual version of the physical system.

As a data scientist, you can improve these simulations. You can:

- Build predictive physics models

- Estimate cutting forces

- Forecast heat generation

- Optimize toolpaths automatically

Imagine using reinforcement learning. The agent tries different strategies. It minimizes cycle time while respecting constraints. It learns the best machining strategy without wasting real material.

That is powerful.

Step 5: Close the Loop with Feedback

Old-school machining was open loop. The machine followed instructions. No questions asked.

Modern machining is smarter.

With feedback systems, machines can adjust in real time. If a sensor detects high load, feed rate can be reduced automatically.

This is control theory in action.

But you can go further with predictive control. Instead of reacting to problems, anticipate them.

For example:

- Predict chatter before it happens

- Adjust parameters dynamically

- Reduce scrap rate

- Extend tool life

This turns CNC machines into adaptive systems.

And adaptive systems are driven by data.

Step 6: Think in Terms of Cost and Value

At the end of the day, machining is a business.

Every minute of spindle time costs money. Every scrapped part reduces profit.

Data science can directly impact:

- Production throughput

- Inventory planning

- Maintenance scheduling

- Quality control

Predictive maintenance is a big one.

If you can forecast when a spindle bearing will fail, you can schedule downtime proactively. No surprise breakdowns. No halted production.

Use classification models for defect detection. Use regression for cycle time estimation. Use clustering to group similar part families.

Bring your full toolkit.

Step 7: Connect Design and Manufacturing Data

Here is where things get exciting.

Most companies treat design and manufacturing as separate worlds. But they should be connected.

Design choices affect machinability. Thin walls may vibrate. Tight tolerances increase cycle time.

If you analyze historical production data, you can give feedback to designers.

For example:

- Suggest geometry changes to reduce machining time

- Highlight features that cause defects

- Estimate cost impact of design revisions

This is called Design for Manufacturability.

You are building a bridge between virtual design and physical reality.

Step 8: Start Simple

You do not need a PhD in mechanical engineering to contribute.

Start small.

Pick one problem:

- Tool wear prediction

- Cycle time estimation

- Scrap classification

Gather data. Build a baseline model. Deploy it quietly. Measure improvement.

Manufacturing teams care about results. Not buzzwords.

Be practical.

Common Challenges (And How to Handle Them)

1. Limited Data

Manufacturing datasets are often small. Use domain knowledge. Engineer strong features. Consider transfer learning.

2. Resistance to Change

Machine operators trust experience. Respect that. Combine statistical insight with shop floor wisdom.

3. Noisy Environments

Factories are chaotic. Use robust preprocessing. Validate carefully. Avoid overfitting.

4. Integration with Legacy Systems

Many machines are old. Data access can be tricky. Be creative. Use edge devices or retrofit sensors.

Manufacturing is messy. But that makes it interesting.

Your New Mental Model

Here is the big shift.

Stop thinking of CNC machining as just hardware. Think of it as a data-driven cyber-physical system.

Inputs:

- Design geometry

- Process parameters

- Material properties

Outputs:

- Physical parts

- Surface finish quality

- Production metrics

Between input and output lies computation. Optimization. Prediction. Control.

That is your playground.

From Dashboard to Drill Bit

Most data scientists never see their work in physical form. They ship models. They monitor metrics. They update notebooks.

But when you work with CNC machining, your impact becomes tangible.

You hold the part. You feel its weight. You see the surface finish. You know data helped create it.

That is deeply satisfying.

From data to parts. From numbers to metal. From prediction to precision.

The factory floor is waiting.